"Amoore100" (amoore100)

"Amoore100" (amoore100)

10/01/2014 at 21:22 Filed to: None

1

1

28

28

"Amoore100" (amoore100)

"Amoore100" (amoore100)

10/01/2014 at 21:22 Filed to: None |  1 1

|  28 28 |

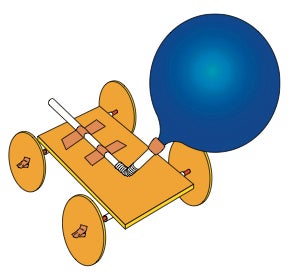

For my AP Physics class we have to make a car that runs only on the air propelled from a balloon and it has to go at least 15 meters. I have until October 17 to do it with a group and was wondering if you guys had any ideas for a good design?

Currently the only restrictions are that it must be 25 x 17 square cm footprint and you can't use prefabricated materials.

I was thinking of aluminum tubing axles, as I did for my mousetrap cars in eighth grade, on a lightweight chassis of whoknowswhat (I was thinking cardboard, then balsa wood, then carbon fiber because why the hell not...how much does it cost nowadays?) The wheels could be CDs or something more complicated, I don't know what, then put an aero bodykit on it that's relatively light made of cardboard or paper or cloth or Kevlar or I don't know...then a balloon mounting location and that's it! No idea how it should look, I don't want it to be too complicated but I want it to run well and stand apart from the others!

(i.e. <- not this...)

So, looking for any ideas or suggestions of a design...if it's a really good idea, I'll give you credit! XD

Edit: Forgot to say this: torque steer should be minimized... ;)

norskracer98-ExploringTheOutback

> Amoore100

norskracer98-ExploringTheOutback

> Amoore100

10/01/2014 at 21:24 |

|

So basically you want to make something that's gonna cost about the same as a BMW?

For Sweden

> Amoore100

For Sweden

> Amoore100

10/01/2014 at 21:25 |

|

Head loss will be your enemy. Make the distance from the balloon opening to your nozzle as short and straight as possible.

That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

> norskracer98-ExploringTheOutback

That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

> norskracer98-ExploringTheOutback

10/01/2014 at 21:26 |

|

CDs for wheels is a good idea, though I'd probably go smaller...like those little mini CDs, or the disc inside a PSP's UMD. Very low rolling resistance. You could also go with styrene tubing for axles, I think that would save you a bit of weight over aluminum, though you'd want some kind of a bushing for them to ride in.

DoYouEvenShift

> Amoore100

DoYouEvenShift

> Amoore100

10/01/2014 at 21:34 |

|

Hmmmm..

Low rolling resistance, low ride height, maybe have the ballon blow onto an impeller on the axle that turns it? Also experiment with different sized nozzles to control the rate of air release. Sounds like a fun project.

ly2v8-Brian

> Amoore100

ly2v8-Brian

> Amoore100

10/01/2014 at 21:34 |

|

Balsa wood for a chassis. metal tubing for axles. Pinewood derby car plastic wheels. Reduce rolling resistance with graphite powder. The key is getting the most out of your propellent. If your feeling adventurous focus the air blast from the balloon on a paddle wheel like gear on one of the axels.

dogisbadob

> Amoore100

dogisbadob

> Amoore100

10/01/2014 at 21:37 |

|

3-inch CD's would make decent wheels, probably much easier to deal with than regular size CD's. And you can give them camber stance yo

A piece of cardboard for the chassis, like maybe the end of a cardboard box

Nibby

> Amoore100

Nibby

> Amoore100

10/01/2014 at 21:47 |

|

Add lightness.

midengineer

> DoYouEvenShift

midengineer

> DoYouEvenShift

10/01/2014 at 22:03 |

|

My first thought was the air driving the axle too but for it to be really efficient I would think that you'd need a closed system to ensure that minimal air is wasted. How would you make one without adding too much weight... Now I'm just typing my thoughts as I go along. This has really piqued my curiosity.

Squid

> Amoore100

Squid

> Amoore100

10/01/2014 at 22:05 |

|

So you need to make your own wheels, I guess you could do a balsa chassis, with balsa wheels and a plastic cone for air deflection over the balloon to keep it in place and not flopping around. Also try to figure out a way to play with nozzle sizes to control the rate of gas flow. Are there any restrictions on type of balloon used? volume of gas to be put in the balloon? Material the balloon is made from? I would find the thickest walled, hardest to blow up balloon out there so effectively you have more pressure to work with which in turn could yield more propulsion. Also, make sure to use plenty of lube on your axles, if you make them out of balsa try to find a hard urethane varnish to put on the axle hole and slather that with lube. I think that the lightest weight over every aspect along with maximum gas volume and pressure being released in a controlled manner will get you pretty damn far. You could go for minimal thrust but long duration or maximal thrust short duration and see the difference in distance it travels, you could go the slow and steady route and make it go ridiculously far but really really slowly. It also depends on the surface you will be performing the test on. I don't know if any of this will help you, but good luck and have fun with it.

ttyymmnn

> Amoore100

ttyymmnn

> Amoore100

10/01/2014 at 22:06 |

|

No restriction on the size of the balloon? Hmmm.....

My kids have those thick rubber balloons with an elastic strap tied to it. You blow it up and bop it sort of like a punching bag. I think you might bet a pretty good amount of pressure out of one of those. Might be a bitch to mount, though.

Might also be some ideas to steal from here: http://www.balloonhq.com/balloon_car/ba

Boss2452stolemylunchmoney

> Amoore100

Boss2452stolemylunchmoney

> Amoore100

10/01/2014 at 22:08 |

|

In the interest of weight, I would go full cardboard chassis. Glue on cardboard ribs lengthwise for structural rigidity. I like the idea of using cd's as wheels; they are very precisely round, light, large, and stiff... All good things for what you're going for. What you're going to need to do is figure out a way to make a bearing surface to go between the cd's and the axles, which I agree should be aluminum. My first thought is to epoxy some washers on either side of each cd, using some kind of jig to make sure everything stays centered... Don't do that, it's stupid. My second thought is to get an aluminum tube that is just slightly smaller than the center of the cd's. You'll want to lubricate this with plenty of graphite dry lubricant. Your next challenge will be to make sure the axles are precisely parallel and secure them to the cardboard. You're going to use the axles to provide stiffness to the chassis as well... So be mindful how you mount them.

DoYouEvenShift

> midengineer

DoYouEvenShift

> midengineer

10/01/2014 at 22:43 |

|

I thought about that too, like the way a turbo is enclosed. Another idea would be to build the drive wheels so that the spokes double as impellers. And have tubing split from the ballon onto each wheel.

I have a history of overcomplicating everything.

Brickman

> Amoore100

Brickman

> Amoore100

10/01/2014 at 23:57 |

|

Add Sharpie marker flames. Adds power :D

midengineer

> DoYouEvenShift

midengineer

> DoYouEvenShift

10/02/2014 at 00:00 |

|

Right there with you, I'm tempted to try it.

Amoore100

> Brickman

Amoore100

> Brickman

10/02/2014 at 00:02 |

|

that and stickers... ;D

Amoore100

> DoYouEvenShift

Amoore100

> DoYouEvenShift

10/02/2014 at 00:03 |

|

HAH! Car guy thinking...I was thinking of having the air turn a turbine/prop as well...turbo (kinda) ftw! Of course, too much spinning resistance...

Amoore100

> norskracer98-ExploringTheOutback

Amoore100

> norskracer98-ExploringTheOutback

10/02/2014 at 00:04 |

|

YES... XD

Amoore100

> ttyymmnn

Amoore100

> ttyymmnn

10/02/2014 at 00:10 |

|

unfortunately, my teacher's supplying a 9 inch balloon...

Amoore100

> dogisbadob

Amoore100

> dogisbadob

10/02/2014 at 00:10 |

|

camber!

Amoore100

> ly2v8-Brian

Amoore100

> ly2v8-Brian

10/02/2014 at 00:10 |

|

good ideas, all of them...

Amoore100

> Boss2452stolemylunchmoney

Amoore100

> Boss2452stolemylunchmoney

10/02/2014 at 00:11 |

|

details! awesome, will be sure to read them...

Amoore100

> Squid

Amoore100

> Squid

10/02/2014 at 00:11 |

|

also, great advice, will be sure to read!

Transit

> Amoore100

Transit

> Amoore100

10/02/2014 at 09:47 |

|

The balloon wants to dump all the air out in a hurry and flop your car about like an un-sprung mousetrap. Get a few small drill bits and make a venturi style nozzle to restrict the flow to just enough so the car moves forward. Then if your car is light and has low rolling resistance, it'll go a long ways.

Amoore100

> Transit

Amoore100

> Transit

10/02/2014 at 10:48 |

|

ooh, I hadn't thought of that...thanks!

Captain of the Enterprise

> Amoore100

Captain of the Enterprise

> Amoore100

10/02/2014 at 11:45 |

|

I would go for fiberglass over carbon fiber because of cost, also would consider the size of the cart and experiment with different balloon types and flow rates of the air coming out of them.

Amoore100

> Captain of the Enterprise

Amoore100

> Captain of the Enterprise

10/02/2014 at 18:55 |

|

ooh, fiberglass, i like that...

Captain of the Enterprise

> Amoore100

Captain of the Enterprise

> Amoore100

10/03/2014 at 08:57 |

|

Plus fiberglass is a lot safer to work with, carbon fiber work requires a respirator, safety glasses and a full safety suit from head to toe to protect you from the carbon fiber shaving that can get stuck in your skin, eyes and respiratory system so I would avoid it if at all possible. As for fiberglass its pretty cool, lightweight and looks good painted but the surface will only be as good as the mold you lay it on and the bodywork you to after.

Amoore100

> Captain of the Enterprise

Amoore100

> Captain of the Enterprise

10/03/2014 at 19:12 |

|

eheh, yeah...